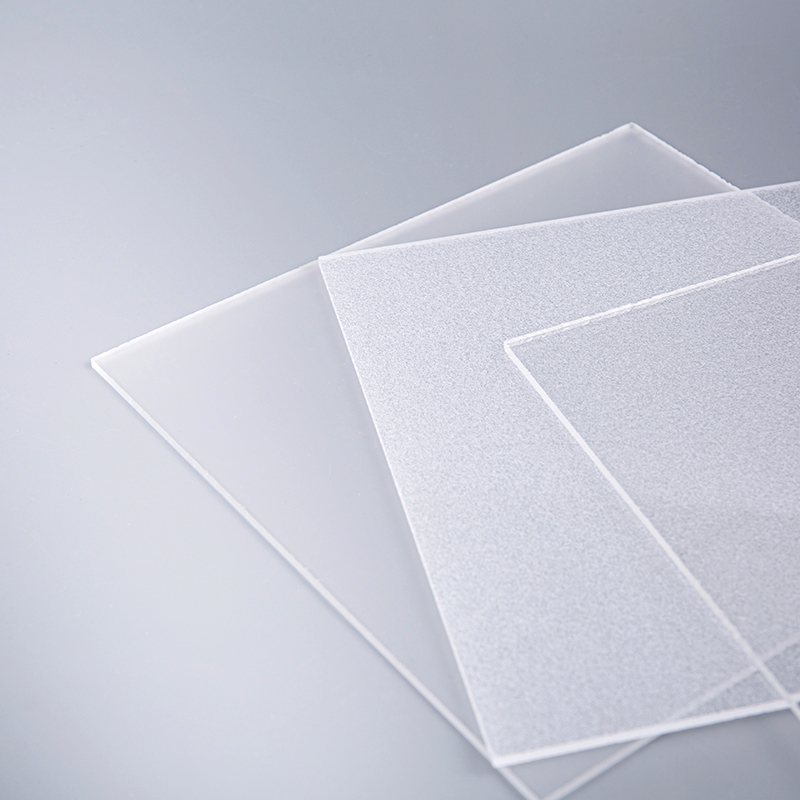

High-Strength Clear Acrylic Sheet

One of Oleg's popular products is the clear acrylic sheet, and our strong production capacity ensure...

Navigating the world of plastic sheeting can be a complex task, especially when your project demands the unique combination of strength, clarity, and versatility that thick acrylic sheets provide. Unlike their thinner counterparts, these robust panels serve as a reliable material for a multitude of heavy-duty applications, from architectural features to protective barriers. The decision to purchase online offers unparalleled convenience and access to a wide range of options, but it also requires a discerning eye for quality and value. This comprehensive guide is designed to demystify the process, empowering you to make an informed purchase. We will delve into the critical aspects of selecting the right material, understanding its properties, and identifying the best sources for procuring high-grade acrylic sheets that meet your specific requirements without compromising on performance or budget. The following sections will provide a detailed roadmap, ensuring you are well-equipped to find the perfect balance between superior quality and competitive pricing in the online marketplace.

To effectively find the specific products you need, incorporating precise search terms is crucial. The following long-tail keywords are selected for their relevance, potential search traffic, and lower competition, making them excellent targets for your online research. Each phrase addresses a specific need or question a potential buyer might have.

Thick acrylic sheets, typically defined as those over 1/4 inch (6mm) in thickness, are engineering-grade materials chosen for projects where durability and structural integrity are non-negotiable. Their application spectrum is vast and varied, spanning numerous industries and DIY endeavors.

The robustness of thick acrylic makes it suitable for scenarios where glass would be too heavy or fragile. Its high impact resistance, which can be up to 17 times greater than glass, is a primary reason for its selection in public spaces and high-traffic areas. Furthermore, its exceptional light transmission and weatherability make it a preferred material for both indoor and outdoor use.

When comparing thick acrylic to other common materials like polycarbonate or glass, several distinct advantages emerge. The following table provides a clear, side-by-side comparison to illustrate these differences.

When selecting a material for a project, it is essential to weigh the properties of each option. For instance, while polycarbonate has a higher impact strength, acrylic offers superior clarity and resistance to yellowing over time, making it a better choice for applications where aesthetics and long-term clarity are paramount, such as in thick acrylic sheets for outdoor signage. Glass, while scratch-resistant, is heavy and hazardous when broken, whereas acrylic is lightweight and shatter-resistant.

| Material | Impact Strength | Light Transmission | Weight | UV Resistance | Cost |

|---|---|---|---|---|---|

| Thick Acrylic | High (Up to 17x glass) | Excellent (92%) | Lightweight (Half of glass) | Excellent | Moderate |

| Polycarbonate | Very High (Up to 250x glass) | Good (88%) | Lightweight | Good (with coating) | Higher |

| Glass | Low | Excellent (89-90%) | Heavy | Excellent | Varies |

A critical decision point in purchasing thick acrylic sheets is choosing between the two primary manufacturing types: cast and extruded. This choice significantly influences the material's performance, workability, and suitability for your project.

Cast acrylic is produced by pouring a liquid acrylic mixture between two glass sheets and then curing it in an oven. This process results in a sheet with excellent optical quality, high molecular weight, and superior chemical resistance. It is the preferred material for applications requiring precision machining, deep forming, and exceptional weatherability. For projects that demand maximum durability, an impact resistant thick cast acrylic sheet is often the gold standard. Its internal structure allows it to withstand significant force without cracking or shattering, making it ideal for security glazing, high-end displays, and architectural features that are exposed to the elements. Furthermore, cast acrylic is easier to thermoform and polish, yielding cleaner edges and a more professional finish on fabricated pieces.

Extruded acrylic is manufactured by pushing a heated acrylic compound through a series of rollers to form a continuous sheet. This method is more cost-effective and efficient, resulting in a product that is generally less expensive than cast acrylic. Extruded sheets have a more consistent thickness tolerance and are excellent for applications involving simple cutting and bending. However, they have a lower molecular weight, which can make them more susceptible to stress cracking when laser cutting or machining, and they may not offer the same level of chemical resistance as cast acrylic. The choice between the two often comes down to the specific fabrication processes involved and the environmental conditions the final product will face.

Purchasing the correct thick acrylic sheet goes beyond just selecting a thickness. Several technical specifications directly impact the sheet's performance and longevity. Paying close attention to these details will ensure the material you receive is perfectly suited for its intended application.

Thickness is the most obvious specification, but it's essential to understand the tolerance, which is the allowable deviation from the stated thickness. For example, a 1-inch thick sheet might have a tolerance of ±10%, meaning its actual thickness could vary between 0.9 and 1.1 inches. For structural applications, a tighter tolerance is critical. Thickness directly correlates with rigidity and load-bearing capacity. A thicker sheet will be more rigid and less prone to bending under its own weight or external pressure, a crucial factor for large panels like those used in thick acrylic sheets for outdoor signage that must resist wind loads.

The primary reason for choosing acrylic over other plastics is often its glass-like clarity. This is measured by light transmission percentage. High-quality optical-grade acrylic can transmit up to 92% of visible light, rivaling and even surpassing glass. For applications like a clear thick acrylic sheet for aquarium tanks or retail display cases, this property is non-negotiable. Any haze, yellowing, or distortion can significantly detract from the visual appeal of the final product. It is also important to consider the surface finish; a polished edge will maintain clarity, while a rough-cut edge can appear white and cloudy.

For any outdoor application, UV stability is a paramount concern. Prolonged exposure to sunlight can cause many plastics to yellow, become brittle, and crack. High-quality acrylic sheets are manufactured with built-in UV stabilizers that absorb harmful radiation, preventing degradation and maintaining clarity and strength for decades. This makes an impact resistant thick cast acrylic sheet with high UV stability an excellent choice for skylights, greenhouse panels, and external signs. Weather resistance also includes the ability to withstand temperature fluctuations, rain, and snow without warping or losing structural integrity.

Many suppliers offer value-added services that can save you time, reduce material waste, and ensure a professional result. Leveraging these services is particularly important when working with thick acrylic, which can be challenging to cut and finish without specialized equipment.

Attempting to cut thick acrylic sheets with standard tools can lead to chipping, cracking, or imprecise edges. A professional custom size thick acrylic sheet cutting service utilizes computer-controlled (CNC) routers or lasers to deliver precise, clean cuts according to your exact specifications. This service is invaluable for several reasons. It guarantees dimensional accuracy, which is crucial for parts that need to fit together perfectly. It also produces smooth, ready-to-use edges that often require no additional polishing. Furthermore, it allows you to order exactly the size you need, minimizing waste and potentially reducing shipping costs for smaller, pre-cut pieces. When planning a complex project with multiple unique shapes, a custom cutting service is practically essential.

The edge of a cut acrylic sheet can be finished in several ways, each offering a different aesthetic and functional quality. A machined edge straight from a CNC router is typically smooth but will have a translucent appearance. For a crystal-clear, glass-like edge, a flame polishing or mechanical polishing process is required. Other options include beveled edges, which are both decorative and safer by eliminating sharp corners, and routed edges for decorative grooves. Discussing these options with your supplier ensures the final product meets your visual and safety standards.

Joining thick acrylic panels requires careful consideration, as the wrong adhesive can lead to weak bonds, clouding, or even cracking of the material. Achieving an invisible and structurally sound bond is a key skill in acrylic fabrication.

Selecting the best adhesive for bonding thick acrylic panels is critical for the structural integrity and appearance of your project. Not all glues are suitable for acrylic, and some can permanently damage it. The goal is to use an adhesive that actually fuses the acrylic surfaces together at a molecular level, creating a bond that is often as strong as the material itself. Solvent-based cements are the standard for this purpose. They work by softening the surfaces of the acrylic, allowing the polymer chains to intermingle, and then evaporating to leave a solid, monolithic piece of plastic. For thick sheets, a low-viscosity cement is often recommended because it can wick into the joint via capillary action, ensuring a deep and complete bond.

Proper technique is as important as the adhesive itself. The surfaces to be bonded must be clean, dry, and perfectly fitted. Any gap can lead to a weak joint. The adhesive is typically applied using a specialized applicator bottle with a needle-like tip or a syringe, which allows for precise control and minimizes mess. The parts are then clamped together under light pressure until the solvent has evaporated and the bond has set. It's important to work in a well-ventilated area and to allow sufficient curing time, which can be longer for thicker panels, before subjecting the assembly to any stress. Mastering this process is essential for projects like building an aquarium or a complex display case where the bond must be both strong and optically clear.

Buying thick acrylic sheets online requires a methodical approach to ensure you receive a product that matches its description and is delivered safely. Knowing what to look for on a supplier's website and which questions to ask can prevent costly mistakes.

Before placing an order, invest time in researching the supplier. Look for detailed product specifications, clear photographs, and transparent information about material origin (e.g., cell cast vs. continuous cast). Customer reviews and testimonials can provide insight into the experiences of previous buyers, particularly regarding the accuracy of the product description and the quality of the customer service. A reputable supplier will be happy to answer technical questions about their sheets, such as the UV stabilizer content, the exact tolerance standards, and the type of protective masking film used. They should also provide clear information about their custom size thick acrylic sheet cutting service if offered, including pricing and tolerance for custom work.

Thick acrylic sheets are large, heavy, and susceptible to scratching and cracking if not handled properly. A reliable supplier will have robust packaging protocols, often involving cardboard corner protectors, foam separators, and a sturdy cardboard or wooden crate. Carefully review the shipping costs and methods, as freight shipping is typically required for large, thick panels. Also, thoroughly read the return policy. Understand the conditions under which a return is accepted, who bears the cost of return shipping (which can be substantial), and what constitutes acceptable condition for a return. This due diligence is your best defense against receiving a damaged or incorrect product and being unable to remedy the situation.