Anti-UV Cast Acrylic Sheet: How to achieve lasting protection and aesthetic integration?

In the fields of architecture, art installations and industrial design, Anti-UV Cast Acrylic Sheet is redefining the material application standards with its "double excellence in protection and aesthetics". Its core value lies not only in its physical performance of resisting ultraviolet erosion, but also in the deep integration of material function and visual expression through technological breakthroughs. As an industry pioneer, Hangzhou Oleg International Trade Co., Ltd. has pushed the protective life and aesthetic potential of this material to a new height through ten years of technological accumulation.

The protective ability of Anti-UV Cast Acrylic Sheet comes from innovation at the molecular level. Traditional acrylic is prone to yellowing and brittleness under long-term exposure to ultraviolet rays, and Hangzhou Oleg International Trade Co., Ltd. uses a "triple protection system" to solve this problem:

Light stabilizer modification: Through the synergistic effect of nano-level ultraviolet absorbers and hindered amine light stabilizers (HALS), 99% of UVA/UVB band radiation can be intercepted, making the material's light transmittance attenuation rate in outdoor environments less than 5%/year.

Molecular chain strengthening: Adjust the polymerization process of methyl methacrylate (MMA) monomer to form a dense cross-linked network, significantly improving impact resistance and thermal stability. Experimental data show that its impact strength reaches 18kg·cm/cm², which is 12 times that of ordinary glass.

Surface coating technology: The independently developed fluorocarbon coating has both hydrophobicity and self-cleaning functions, which can reduce the adhesion of stains and reduce the direct damage of ultraviolet rays to the surface of the material.

This technical system has been verified in the curtain wall renovation of Hangzhou International Jewelry City. The project uses anti-UV panels customized by Hangzhou Oleg International Trade Co., Ltd., with a transmittance retention rate of 87% over ten years, while the similar data of traditional glass curtain walls is only 65%.

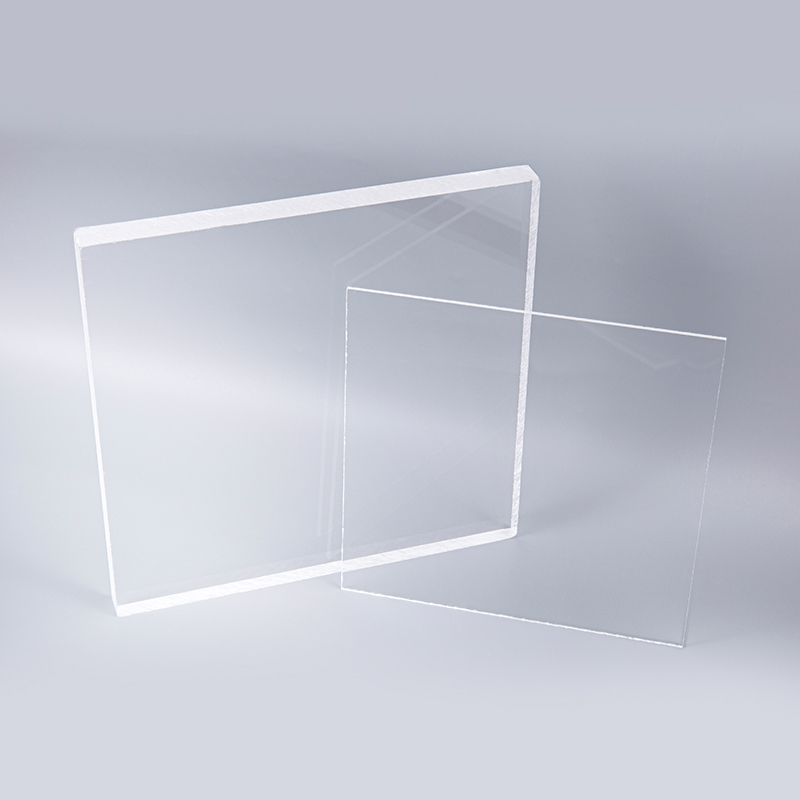

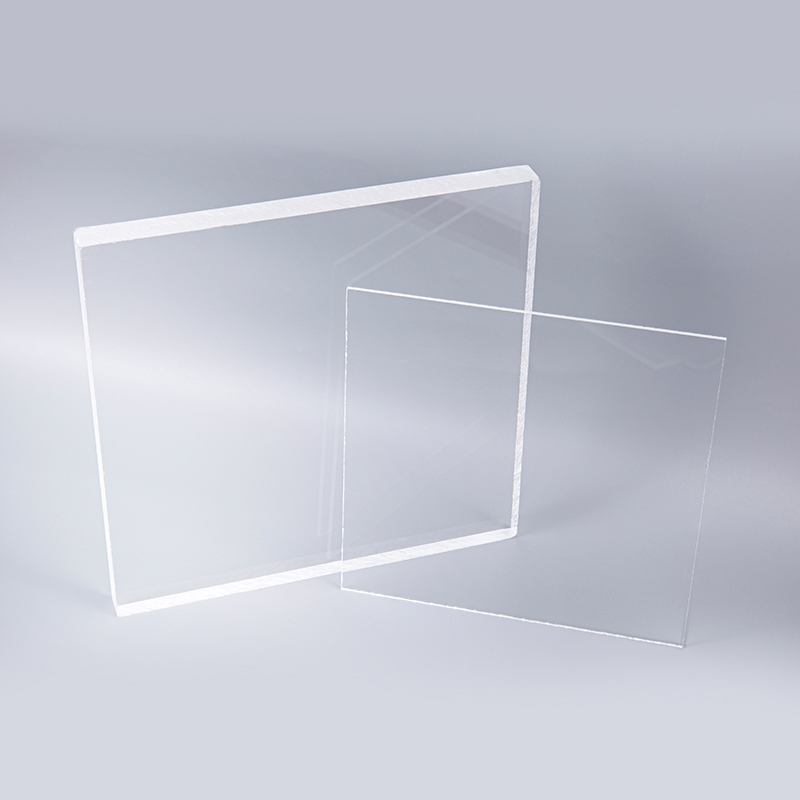

The aesthetic value of anti-UV cast acrylic panels is reflected in the dual evolution of "transparency" and "plasticity". Its high light transmittance (92%) and low haze (0.8%) make the material realize "light and shadow magic" in the fields of building skylights, art installations, etc.:

Architecture: UV-resistant acrylic sheets processed by hot bending technology create a "flowing light and shadow" visual effect while ensuring structural strength by precisely controlling the bending radius (minimum 500mm).

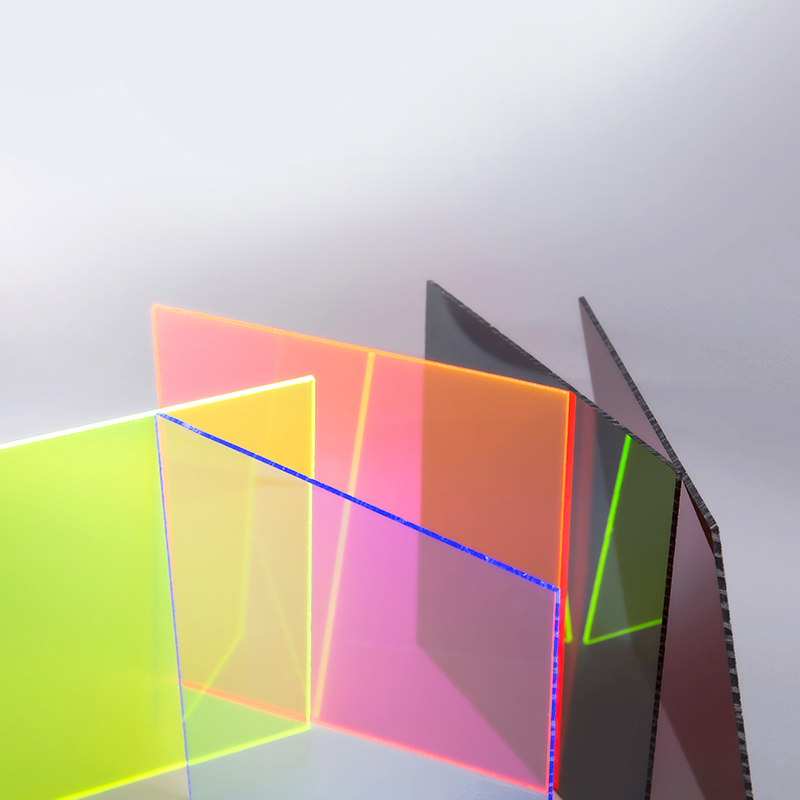

Art installation: Artists use its surface hardness (pencil hardness up to 4H) for laser engraving, combined with the weather resistance of the UV-resistant coating, to create public art works that can be displayed outdoors for a long time. A landmark sculpture project in a certain city still maintains pattern clarity after five years of wind and sun exposure.

Industrial design: In the field of high-end furniture, UV-resistant acrylic sheets achieve complex curved surface modeling through injection molding, and its surface scratch resistance (Mohs hardness level 6) makes the product both practical and design-oriented.

From a "protective shield" against ultraviolet rays to a "canvas" that shapes the aesthetics of light and shadow, the evolution of UV-resistant cast acrylic sheets is a vivid portrayal of material science breaking through functional boundaries and empowering multiple scenarios. When the decade of technological accumulation of Hangzhou Oleg International Trade Co., Ltd. meets the wave of future technology, this material will surely bloom with unique value in more fields.