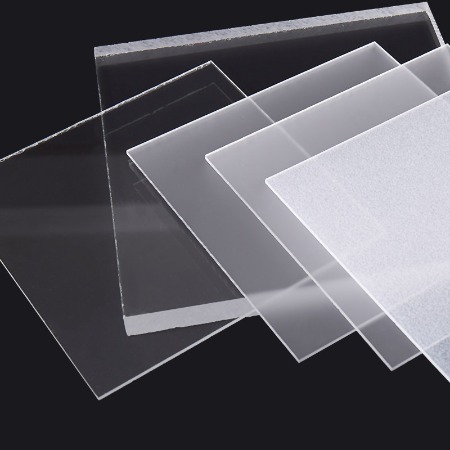

High-Strength Clear Acrylic Sheet

One of Oleg's popular products is the clear acrylic sheet, and our strong production capacity ensure...

Polymethyl methacrylate (PMMA) sheets, commonly referred to as acrylic glass or plexiglass, represent one of the most versatile thermoplastic materials available today. These transparent plastic sheets combine exceptional optical clarity with remarkable durability, making them suitable for countless applications where traditional glass would be impractical or unsafe. PMMA sheets typically transmit about 92% of visible light (comparable to optical glass) while weighing less than half of equivalent glass thickness.

The molecular structure of PMMA gives it several unique advantages over other transparent materials. The polymer chains contain ester groups that provide excellent UV resistance and weatherability, allowing PMMA sheets to maintain their clarity and mechanical properties even after years of outdoor exposure. Furthermore, the material's inherent resistance to many chemicals makes it suitable for laboratory and industrial environments where corrosion resistance is crucial.

Hangzhou Oleg International Trade Co., Ltd has established itself as a leader in PMMA sheet manufacturing through its state-of-the-art production facility in Huzhou. Their 50,000 square meter manufacturing plant represents the largest PMMA production site in Eastern China, equipped with six advanced production lines operated by over 370 skilled technicians. The company's commitment to quality is demonstrated by their rigorous adherence to GB/T7134-2008 standards, often exceeding these requirements through precision system integration and continuous process optimization.

In modern architecture, PMMA sheets have revolutionized design possibilities while improving safety and energy efficiency. Architects increasingly specify acrylic sheets for:

The material's impact resistance (10-20 times greater than glass) makes it particularly valuable in areas prone to severe weather or potential vandalism. Furthermore, PMMA's thermal insulation properties (about 20% better than glass) contribute to energy savings in building applications.

The signage industry relies heavily on PMMA sheets due to their exceptional light transmission and surface quality. Key applications include:

Unlike polycarbonate, PMMA sheets resist yellowing from UV exposure, ensuring that signs maintain their visual impact over time. The material's surface hardness (about 2H on the pencil hardness scale) also makes it more scratch-resistant than many alternative plastics.

While both PMMA and polycarbonate (PC) sheets serve as transparent plastic alternatives to glass, their material properties differ significantly, making each suitable for distinct applications. The following table provides a comprehensive comparison:

| Property | PMMA Sheets | Polycarbonate Sheets |

|---|---|---|

| Light Transmission | 92% (superior clarity) | 88% (slight yellowish tint) |

| Impact Resistance | Good (10-20x better than glass) | Excellent (250x better than glass) |

| Surface Hardness | 2H pencil hardness (more scratch resistant) | HB pencil hardness (easier to scratch) |

| UV Stability | Excellent (naturally UV resistant) | Good (requires UV coating) |

| Thermal Resistance | Continuous use up to 70°C | Continuous use up to 120°C |

| Chemical Resistance | Resistant to many chemicals except strong solvents | Prone to stress cracking with certain chemicals |

This comparison reveals that PMMA sheets generally outperform polycarbonate in applications requiring optical clarity, weather resistance, and surface durability, while polycarbonate remains the choice for extreme impact resistance and higher temperature applications.

Choosing the right thickness for PMMA sheets involves careful consideration of multiple factors including structural requirements, weight limitations, and cost considerations. The thickness directly affects:

Manufacturers like Hangzhou Oleg International Trade Co., Ltd typically offer PMMA sheets in these standard thicknesses:

The production process significantly impacts the final quality of PMMA sheets. Hangzhou Oleg International Trade Co., Ltd employs advanced cell casting technology that ensures superior optical and mechanical properties compared to extruded acrylic. Their manufacturing process involves:

Starting with high-purity methyl methacrylate monomer, the process includes:

The actual sheet formation occurs in carefully controlled conditions:

After demolding, each sheet undergoes:

This meticulous approach enables Hangzhou Oleg International Trade Co., Ltd to produce cast acrylic sheets with exceptional consistency and quality, supporting their position as a leading OEM Architectural Acrylic Panels Factory in the global market.