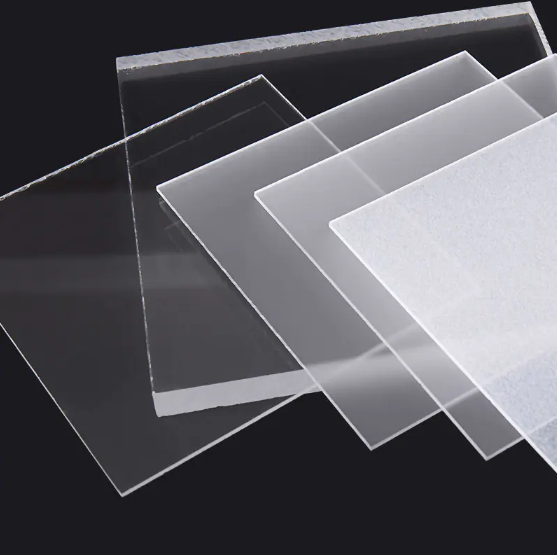

High-Strength Clear Acrylic Sheet

One of Oleg's popular products is the clear acrylic sheet, and our strong production capacity ensure...

PMMA, or Polymethyl Methacrylate, is a transparent thermoplastic often used as a lightweight or shatter-resistant alternative to glass. It is commonly known by brand names such as Plexiglas, Lucite, and Perspex. PMMA is produced through the polymerization of methyl methacrylate monomers, resulting in a material that offers excellent optical clarity and durability.

PMMA exhibits several key properties that make it suitable for various applications:

Compared to other materials like glass and polycarbonate, PMMA offers a balance between cost, performance, and aesthetics. While polycarbonate is more impact-resistant, PMMA provides superior optical clarity and is more scratch-resistant. Glass, on the other hand, is heavier and more prone to breakage.

PMMA sheets are widely used in the signage industry due to their clarity and ease of fabrication. Applications include:

In design and architecture, PMMA sheets are used for:

PMMA is also utilized in various industrial applications:

When selecting PMMA sheets, consider the level of transparency required for your application. High-transparency sheets are essential for applications like display cases and signage where clear visibility is crucial.

For outdoor applications, choose PMMA sheets with UV resistance to prevent yellowing and degradation over time. Weather-resistant sheets are necessary for exposure to varying environmental conditions.

Assess the level of impact resistance needed based on the intended use. PMMA offers good impact resistance, but for areas with high risk of impact, consider materials with higher resistance like polycarbonate.

The thickness and size of the PMMA sheets should align with the structural requirements of your project. Thicker sheets provide greater strength but may be heavier and more challenging to work with.

Consider whether to source PMMA sheets from domestic or international suppliers. Domestic suppliers may offer faster delivery times, while international suppliers might provide cost savings.

Ensure that the supplier can accommodate your shipping needs, including delivery times and packaging to prevent damage during transit.

Many suppliers offer customization services, such as cutting to size, engraving, and color options, to meet the specific requirements of your project.

Regular cleaning with a soft cloth and mild detergent can maintain the clarity of PMMA sheets. Avoid abrasive materials that can scratch the surface.

Handle PMMA sheets carefully to prevent scratches and other damage. Use protective films during installation and transport.

Over time, PMMA sheets may accumulate dirt and grime. Periodic cleaning and maintenance can extend the life and appearance of the material.

Cast acrylic sheets are made by pouring liquid acrylic into a mold, resulting in a sheet with superior optical clarity and chemical resistance. Extruded acrylic sheets are produced by forcing melted acrylic through a die, offering lower cost and better consistency in thickness but with slightly reduced optical quality.

PMMA sheets can be cut using various methods, including scoring and snapping for thinner sheets, or using a saw with a fine-toothed blade for thicker sheets. It's important to use the appropriate tools and techniques to achieve clean cuts.

Yes, PMMA sheets are suitable for outdoor use due to their UV resistance and weatherability. However, for applications exposed to harsh conditions, consider sheets with enhanced UV resistance.

PMMA is recyclable, but the recycling process can be complex. It's important to check with local recycling facilities to determine the best practices for recycling PMMA materials.

Regular cleaning with a soft cloth and mild detergent can help maintain the clarity of PMMA sheets. Avoid using abrasive cleaners or materials that can scratch the surface.