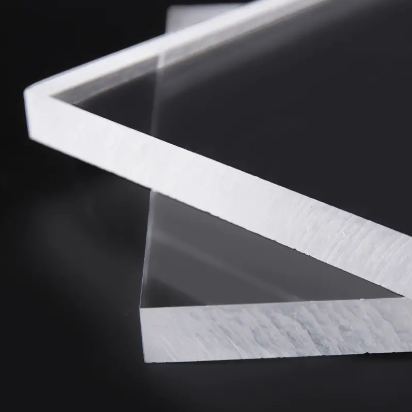

High-Strength Clear Acrylic Sheet

One of Oleg's popular products is the clear acrylic sheet, and our strong production capacity ensure...

The global shift towards environmental responsibility has fundamentally transformed the materials landscape, pushing industries to seek sustainable alternatives without compromising performance. Within this transformative wave, acrylic, a versatile and widely used polymer, has undergone significant green evolution. Traditional acrylic production often relies on petrochemical feedstocks and energy-intensive processes, raising concerns about carbon footprint and long-term ecological impact. However, the emergence of eco-friendly acrylic represents a pivotal advancement, merging the material's inherent benefits—such as exceptional clarity, weather resistance, and formability—with a renewed commitment to planetary health. This paradigm shift is not merely a trend but a necessary response to regulatory pressures, consumer demand for greener products, and the corporate world's increasing embrace of circular economy principles. For manufacturers, specifiers, and end-users, understanding the nuances of sustainable acrylic is now crucial for making informed, responsible choices that align with both project requirements and environmental ethics.

The journey towards sustainable acrylic involves multiple facets, from sourcing raw materials and innovating manufacturing processes to ensuring end-of-life recyclability. It challenges the conventional linear "take-make-dispose" model, advocating for a system where material value is maintained for as long as possible. This guide delves deep into the core aspects of eco-friendly acrylic, exploring its composition, production, applications, and how it compares to other materials. We will also address specific, sought-after queries within this domain, providing clarity on key topics that resonate with designers, architects, and procurement specialists looking for viable, high-performance sustainable solutions. As a leader in this field, Hangzhou Oleg International Trade Co., Ltd. leverages a decade of specialization and one of East China's largest production bases to integrate these very principles of innovation and sustainability into its OLEG cast acrylic sheets, demonstrating that large-scale manufacturing can coexist with environmental stewardship.

The designation "eco-friendly" for acrylic is not a single attribute but a combination of factors across its lifecycle. Primarily, it hinges on the sourcing of raw materials and the manufacturing process. Conventional acrylic (Polymethyl Methacrylate or PMMA) is derived from monomers like methyl methacrylate (MMA), which are predominantly petrochemical-based. Eco-friendly variants innovate at this foundational stage by incorporating bio-based or recycled content.

Therefore, when evaluating an acrylic sheet's eco-credentials, one must consider its composition, the energy footprint of its production, its durability in application, and its recyclability potential. Certifications, environmental product declarations (EPDs), and transparent supply chain data become invaluable tools for verification.

The quest for biodegradable acrylic sheet alternatives is a topic of significant interest and some confusion within the sustainable materials community. Traditional PMMA acrylic is not biodegradable; it is a robust plastic designed for long-term stability. In standard environmental conditions, it will photodegrade very slowly under prolonged UV exposure but not biodegrade through microbial action in a meaningful timeframe. This durability, while a performance benefit, poses an end-of-life challenge if not managed through proper recycling channels.

However, the market is responding with innovative alternatives that address this concern. These are not always "acrylic" in the strict chemical sense but are presented as functional alternatives for specific applications where clarity and formability are needed but biodegradability is a priority.

Let's compare the core characteristics of standard acrylic, recycled-content acrylic, and prominent biodegradable alternatives like Polylactic Acid (PLA) based sheets or cellulose acetate.

The following table outlines a detailed comparison:

| Feature | Standard Cast Acrylic | Eco-friendly Cast Acrylic (with Recycled Content) | Biodegradable Alternatives (e.g., PLA-based) |

|---|---|---|---|

| Primary Raw Material | Petrochemical-based MMA | Mix of petrochemical MMA and post-consumer/industrial recycled PMMA | Renewable resources (e.g., corn starch, sugarcane) |

| Clarity & Optical Quality | Excellent, glass-like (92% light transmittance) | Excellent, can be engineered to match virgin material clarity | Good to Very Good, but can have slight haziness or yellowing tendency |

| Weather & UV Resistance | Outstanding, highly resistant to yellowing and weathering | Outstanding, inherits UV stabilizers from base material | Poor to Moderate, can degrade, become brittle, or discolor under prolonged UV/sun exposure |

| Mechanical Strength | High impact strength (6-17 times that of glass) | High impact strength, comparable to standard | Lower impact strength, more brittle, especially over time or in varying temperatures |

| Thermal & Chemical Resistance | Good thermal stability, resistant to many chemicals | Good thermal stability, resistant to many chemicals | Lower heat deflection temperature; sensitive to solvents and some chemicals |

| End-of-Life Scenario | Recyclable via grinding/thermoforming; not biodegradable | Highly recyclable, promotes circular economy | Compostable in industrial facilities under specific conditions; may not degrade in landfill |

| Best Suited For | Long-term outdoor signage, architectural glazing, aquariums, high-durability displays | All applications of standard acrylic where a lower footprint is desired without sacrificing performance | Short-term indoor displays, event decorations, packaging, products with planned obsolescence where composting is accessible |

In conclusion, while true biodegradable "acrylic" in the conventional sense is not yet a mainstream reality, viable biodegradable alternatives exist for specific, often temporary, applications. For permanent installations requiring decades of service life, high-recycled-content acrylic remains the more responsible and practical eco-friendly acrylic choice, as it ensures performance while actively reducing waste through circular manufacturing. Companies like Hangzhou Oleg International Trade Co., Ltd. focus on enhancing this circular model, ensuring that their high-volume production directly contributes to resource efficiency.

Sourcing from reputable recycled cast acrylic sheet suppliers is a critical step for businesses committed to sustainable procurement. Not all recycled acrylic is created equal, and the supplier's capabilities directly impact the quality, consistency, and environmental integrity of the final product. When evaluating a supplier, several key factors should be scrutinized beyond just the percentage of recycled content claimed.

Choosing a supplier is not just a transactional decision but a partnership in sustainability. It involves aligning with a manufacturer whose operational scale and technical prowess, like that of Hangzhou Oleg International Trade Co., Ltd., ensure that the choice for recycled material does not force a compromise on the project's quality or aesthetic requirements.

Outdoor applications present the most demanding test for any material, requiring resistance to ultraviolet radiation, temperature extremes, moisture, and physical impact. For sustainable materials, this challenge is twofold: they must be durable enough to avoid frequent replacement (a core tenet of sustainability) while maintaining their eco-friendly credentials. This is where UV resistant eco acrylic for outdoor use becomes a critical product category.

High-quality cast acrylic is inherently UV resistant compared to many other plastics. The polymer structure allows it to absorb UV radiation without significant degradation. However, for long-term outdoor exposure—think decades for architectural elements—formulations are enhanced with specialized UV stabilizers and absorbers. In eco-friendly acrylic, these additives must be selected not only for performance but also for environmental compatibility, avoiding heavy metals or harmful compounds that could leach out.

The performance of UV-resistant eco-acrylic can be benchmarked against other common outdoor materials:

| Material | UV & Weather Resistance | Impact Resistance | Environmental Footprint (Production) | Longevity & Maintenance | End-of-Life |

|---|---|---|---|---|---|

| UV Resistant Eco Cast Acrylic | Excellent: Resists yellowing and embrittlement for 10-30+ years. | Excellent: Many times more impact-resistant than glass; good hail resistance. | Moderate to Good: Improved when made with recycled content/bio-monomer; energy-intensive process. | Very Long; requires only occasional cleaning with non-abrasive materials. | Fully recyclable; can re-enter production cycle. |

| Polycarbonate (PC) | Poor without coating: Prone to UV yellowing and hazing. Requires permanent co-extruded UV layer. | Outstanding: Extremely high impact strength. | Moderate: Petrochemical-based; recycling streams are less established than acrylic. | Long if coated; uncoated sheet degrades rapidly outdoors. | Recyclable but challenging due to coatings and potential for bisphenol-A content. |

| Tempered Glass | Excellent: Inert to UV light. | Poor: While stronger than annealed glass, it can still shatter upon severe impact. | High: Very high embodied energy from melting sand at extreme temperatures. | Very Long but permanent; if broken, requires full replacement. | Recyclable, but mixed glass often downcycled. |

| HDPE (High-Density Polyethylene) Lumber | Good: Contains UV stabilizers but can fade or warp over time. | Good: Durable but can deform under constant load. | Good: Often made from post-consumer recycled plastic (e.g., bottles). | Long; low maintenance but not optically clear. | Recyclable, but quality degrades with each cycle. |

For projects like outdoor signage, protective barriers, architectural canopies, and greenhouses, UV resistant eco acrylic for outdoor use offers a balanced solution. Its clarity remains stable, it withstands harsh climates, and its production can be optimized for sustainability. Manufacturers serving this niche must ensure their material is not just "acrylic" but is engineered for the long haul. The extensive experience in serving diverse international markets enables companies to tailor solutions—such as specific thicknesses, tints, or textured finishes—that meet the unique structural and aesthetic demands of outdoor projects while upholding environmental principles.

Indoor environments, especially homes, schools, offices, and healthcare facilities, have heightened sensitivity to air quality and material safety. Volatile Organic Compounds (VOCs), plasticizers, and residual monomers from building materials can off-gas over time, contributing to "sick building syndrome" and potential health risks. Therefore, specifying a non toxic acrylic material for indoor projects is a paramount concern for architects, interior designers, and homeowners alike.

Cast acrylic, by its nature, is one of the more inert and stable plastics once fully polymerized. Unlike extruded acrylic or PVC, which may contain more additives, high-quality cast acrylic sheets are typically free from phthalates, bisphenol-A (BPA), and heavy metals. However, the "non-toxic" claim must be validated through the entire production process and the final product's emissions profile.

When comparing materials for indoor use, such as furniture, display cases, room dividers, lighting fixtures, or wall panels, acrylic's non-toxic potential stands out, especially in its eco-friendly form which often emphasizes cleaner chemistry.

| Material | Typical VOC Emissions | Common Additives of Concern | Fabrication Fume Concerns | Ease of Cleaning & Maintenance |

|---|---|---|---|---|

| Non-Toxic Cast Acrylic | Very Low (when fully polymerized and certified) | Minimal; can be formulated without BPA, phthalates. | Low; should be cut with proper ventilation as with any material. | Excellent; can be cleaned with mild soap and water; resistant to many household chemicals. |

| PVC (Vinyl) Sheet | Can be High; may off-gas plasticizers (e.g., phthalates). | Phthalates (as plasticizers), lead stabilizers (in some regions). | High; can release hydrochloric acid and dioxins when heated or burned. | Good; but porous grades can harbor bacteria. |

| Medium-Density Fiberboard (MDF) | High; due to urea-formaldehyde resins used as binder. | Formaldehyde is a known carcinogen and common VOC source. | High dust generation; requires sealing to trap emissions. | Poor; unless laminated or sealed, it is susceptible to moisture damage. |

| Polycarbonate | Low for finished product. | Potential concern over BPA, though often disputed in solid form. | Moderate; can produce fumes when machined. | Good; but scratches easily, affecting clarity. |

| Glass | None from the material itself. | None. | High risk of injury from shards during cutting/breaking. | Excellent; but can show streaks and water spots. |

Specifying a non toxic acrylic material for indoor projects thus requires diligence. It involves choosing a supplier with a proven commitment to quality control and clean production, one whose material data sheets and certifications provide the necessary assurances. For bulk buyers in retail, hospitality, or interior construction, partnering with a manufacturer that integrates these health-focused parameters into its standard production, backed by a decade of refinement and a large-scale, controlled facility, is a strategic step towards creating safer, healthier indoor spaces.

The retail, museum, and exhibition industries rely heavily on displays to present products and artifacts compellingly and protectively. Clarity is king in these applications; any distortion, yellowing, or haze can detract from the visual appeal and perceived value of the displayed item. Simultaneously, there is growing pressure from consumers and corporate sustainability mandates to choose environmentally responsible materials. This creates a specific demand for clear eco acrylic sheet for displays that does not compromise optical performance for green credentials.

The challenge in producing such a sheet is significant. Recycled content, especially post-consumer, can introduce impurities or slight variations that affect light transmission and haze levels. Achieving "crystal-clear" or "optical-grade" quality from recycled feedstock is a testament to a manufacturer's technological capability.

Choosing the right material for a display project involves balancing these optical and physical needs with sustainability goals. The following comparison highlights why clear eco-acrylic is becoming the preferred choice over other options for high-end, sustainability-conscious displays.

| Display Material Option | Optical Clarity & Stability | Weight & Safety | Environmental Consideration | Fabrication Flexibility | Cost Consideration |

|---|---|---|---|---|---|

| Clear Eco Acrylic Sheet (with Recycled Content) | Excellent and stable; does not yellow over time if UV-stabilized. | Lightweight (half the weight of glass); shatter-resistant, safer in public spaces. | Good; reduces plastic waste, lower carbon footprint than virgin acrylic or glass. | Excellent; easily cut, routed, engraved, and thermoformed into complex shapes. | Moderate; can be higher than standard acrylic but offers value via sustainability branding. |

| Standard Clear Glass | Excellent initially, but can show green tint (from iron content). | Heavy; requires stronger support; can shatter dangerously. | Poor; very high embodied energy from manufacturing; transportation weight is high. | Poor; difficult to shape; requires professional cutting and finishing. | Low to Moderate for basic sheets. |

| Virgin Optical Acrylic | Optimum (92%+ transmittance). | Lightweight and shatter-resistant. | Poor; 100% petrochemical feedstock, higher carbon footprint. | Excellent. | Moderate. |

| Recycled PETG (Glycol-modified PET) | Good, but often has higher haze and can yellow slightly over time. | Lightweight and tough. | Very Good; widely recycled feedstock. | Good; thermoforms well but can be softer, scratching more easily. | Low to Moderate. |

For a company specializing in manufacturing cast acrylic sheet like Hangzhou Oleg International Trade Co., Ltd., meeting the demand for clear eco acrylic sheet for displays is a natural extension of its precision system integration. By controlling the entire process from raw material selection to polymerization in one of East China's largest production sites, it can ensure that the high-volume capacity delivers not just reliable quality, but a product that allows brands to tell a cleaner, greener story through their displays.

Adopting eco-friendly acrylic is a strategic decision that extends beyond material selection. It involves a holistic view of the project lifecycle—from design and specification to fabrication, installation, and eventual decommissioning. For bulk buyers across industries like retail, architecture, interior design, and exhibit building, creating a framework for implementation ensures environmental goals are met without sacrificing performance or budget.

First, begin with a clear project sustainability brief. Define what "eco-friendly" means for the specific project: is it prioritized on recycled content, reduced carbon footprint, non-toxicity for indoor air quality, or end-of-life recyclability? This clarity will guide the specification process. Engage with suppliers early. Discuss the project's requirements for clarity, strength, weather resistance (for UV resistant eco acrylic for outdoor use), or non-toxicity (for non toxic acrylic material for indoor projects). Reputable suppliers can provide technical data sheets, samples, and even case studies that demonstrate performance in similar applications.

Second, consider design for disassembly and recycling. How will the acrylic be joined? Mechanical fasteners are preferable to permanent chemical adhesives if future recycling is a goal. Design elements that allow for easy separation of acrylic from other materials at end-of-life. Label components with material identification resin codes to facilitate future sorting.

Third, partner with fabricators who understand the material. Eco-friendly acrylic may have slightly different thermoforming temperatures or machining characteristics. Fabricators should use efficient nesting software to minimize waste from cutting sheets and have a plan for recycling their own scrap (post-industrial waste), ideally returning it to the manufacturer or a dedicated recycler. This closes the loop effectively.

Finally, communicate the choice. Using sustainable materials is a value-add for clients, end-users, and stakeholders. It demonstrates a commitment to innovation and responsibility. Specify the recycled content percentage or the material's environmental certifications in project documentation and marketing materials. This not only validates the investment but also helps raise industry standards by creating demand for transparent, high-performance sustainable materials.

By following this framework and leveraging the expertise of dedicated manufacturers who have invested in the scale and technology to make sustainability viable—such as those with extensive experience in serving diverse international markets and providing specialized solutions for bulk buyers—project teams can confidently integrate eco-friendly acrylic, driving positive change one project at a time.