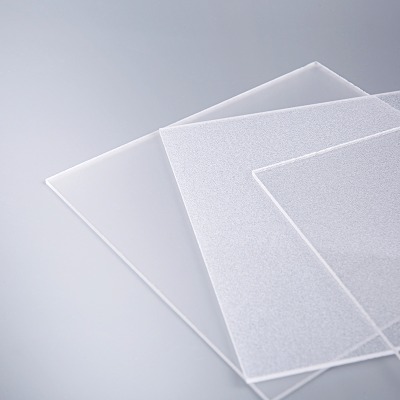

High-Strength Clear Acrylic Sheet

One of Oleg's popular products is the clear acrylic sheet, and our strong production capacity ensure...

For over a decade, Hangzhou Oleg International Trade Co., Ltd. has been at the forefront of manufacturing premium cast acrylic sheet. Our dedicated production facility, one of the largest in East China, embodies our commitment to precision, volume, and quality that consistently meets stringent standards. This guide delves deep into the world of cast acrylic, providing the specific, in-depth information professionals need to make informed decisions for their projects.

Cast acrylic sheet is a high-performance polymer created by pouring a liquid acrylic monomer into a mold or between two glass plates, where it is then cured through a controlled heating process. This meticulous manufacturing method, which we at OLEG have perfected over ten years, results in a material with exceptional optical clarity, superior surface hardness, and excellent chemical resistance.

Choosing the right acrylic type is crucial for project success. While both are poly(methyl methacrylate) or PMMA, their production processes lead to distinct characteristics.

Here is a breakdown of the key differences. The casting process generally produces a sheet with higher molecular weight, which directly influences its performance in areas like machining and chemical resistance. For instance, cast acrylic is less likely to crack or chip during fabrication, making it the preferred choice for intricate CNC machining or laser cutting.

| Property | Cast Acrylic Sheet | Extruded Acrylic Sheet |

|---|---|---|

| Molecular Weight | Higher | Lower |

| Surface Hardness | Superior, more scratch-resistant | Good, but softer |

| Chemical Resistance | Excellent, especially to solvents | Good, but can be prone to stress cracking |

| Thermoforming Consistency | Excellent, heats evenly | Can be variable |

| Thickness Tolerance | Tighter, more precise | Wider tolerance range |

| Optical Clarity | Optimum, often glass-like | Very good |

The unique properties of cast acrylic unlock a vast array of applications across diverse industries, from elegant retail displays to robust marine windows.

The primary advantage is its superior chemical resistance and better thermoforming characteristics due to its higher molecular weight. This makes it ideal for applications involving solvents, intricate forming, or where exceptional edge clarity after machining is required.

Use a soft, lint-free cloth or sponge with a mild soap (like dish detergent) and lukewarm water. Rinse thoroughly and dry with a soft cloth. Never use abrasive cleaners, solvents (like acetone or gasoline), or rough paper towels, as they can scratch or craze the surface.

Yes, but it must be specified as UV-resistant. Standard cast acrylic can degrade under prolonged UV exposure. UV-resistant grades have additives or coatings that protect against yellowing and loss of mechanical strength, making them suitable for long-term outdoor signage, glazing, and architectural features.

It can be precisely cut using CNC routers, laser cutters, or scored and snapped for straight lines (using a specialized acrylic scoring tool). For drilling, use sharp, fluted bits designed for plastics and secure the sheet firmly to prevent cracking. Always allow the tool to do the work without excessive force or heat buildup.

For large-scale projects, a manufacturer with integrated production, like Hangzhou Oleg International Trade Co., Ltd., offers significant advantages: guaranteed supply chain continuity, consistent quality across large batches, more competitive pricing due to scale, and the technical capacity to handle specialized custom requirements for industrial buyers.

Cast acrylic sheet is a versatile and high-performance material whose value is defined by the quality of its manufacture. From understanding the difference between cast and extruded acrylic sheet to selecting a UV resistant cast acrylic sheet for outdoor signs or the best cast acrylic sheet for thermoforming, informed selection is key. Proper fabrication techniques, such as the proper way to polish cast acrylic sheet edges, ensure a professional finish. For substantial requirements, partnering with an established cast acrylic sheet wholesale supplier for large projects ensures reliability, quality, and support. With a decade of specialization, Hangzhou Oleg International Trade Co., Ltd. embodies this commitment to excellence, providing the foundational quality that exceptional projects are built upon.

[1] K. M. B. Jansen, "Weathering of Plastics," in *Plastics and Environmental Sustainability*, Hoboken, NJ, USA: John Wiley & Sons, Inc., 2013, pp. 153–188. (This source provides a general scientific basis for weatherability claims in polymers, supporting the mention of acrylic's performance in outdoor applications like skylights).

[2] A. L. Andrady, "Plastics and Environmental Sustainability," in *Plastics and Environmental Sustainability*, Hoboken, NJ, USA: John Wiley & Sons, Inc., 2015. (This reference supports the general statement on the necessity of UV stabilization for plastics, including acrylic, used in outdoor environments to prevent degradation).