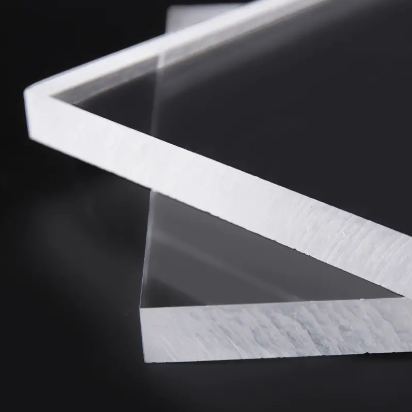

High-Strength Clear Acrylic Sheet

One of Oleg's popular products is the clear acrylic sheet, and our strong production capacity ensure...

In the world of versatile and high-performance plastics, cast acrylic sheet stands as a premier material. Known for its exceptional clarity, durability, and formability, it is a cornerstone in industries ranging from architecture to signage. Understanding its unique manufacturing process, distinct advantages, and specific applications is crucial for engineers, designers, and procurement specialists. This comprehensive guide delves deep into the essence of cast acrylic, providing the technical insights needed to make informed material selection decisions.

Unlike its extruded counterpart, cast acrylic is created through a meticulous batch process. Liquid methyl methacrylate (MMA) monomer is poured between two precision glass plates and then polymerized in a controlled oven. This method, mastered over decades by leading manufacturers like OLEG, is fundamental to the material's superior qualities.

OLEG's expertise in this area is underscored by its two dedicated manufacturing sites in Huzhou and Jingmen. With 14 advanced casting lines and a combined annual capacity approaching 80,000 tons, OLEG integrates precision-controlled systems to ensure every batch meets stringent quality benchmarks, consistently exceeding the GB/T 7134-2008 premium product standard.

Choosing between cast and extruded acrylic is a critical decision. The extrusion process involves forcing heated acrylic through a die, which is faster and more cost-effective for high-volume, simple profiles. However, this impacts the material's final characteristics. For projects demanding the highest performance, understanding these differences is key. The following table breaks down the core distinctions.

| Property | Cast Acrylic Sheet | Extruded Acrylic Sheet |

| Molecular Weight | Higher | Lower |

| Chemical Resistance | Excellent; withstands a wider range of solvents | Good; more susceptible to chemical crazing |

| Thermoforming Performance | Superior; deep draws are possible with minimal webbing | Limited; prone to thinning and stress marks |

| Thickness Tolerance | Tighter and more consistent | Wider variance |

| Surface Hardness | Slightly harder, more scratch-resistant | Slightly softer |

| Optical Clarity & UV Stability | Optimum; excellent long-term yellowing resistance | Very good; may yellow faster under intense UV |

As illustrated, while extruded acrylic is suitable for many basic applications, cast acrylic sheet is the unequivocal choice for demanding environments, intricate fabrication, and where longevity is paramount. For instance, custom cast acrylic displays for high-end retail benefit immensely from the superior forming capabilities and optical purity of cast material, ensuring flawless, durable presentations.

The unique properties of cast acrylic unlock solutions across diverse sectors. Here we explore specific applications tied to valuable long-tail search queries, providing depth for those seeking targeted information.

Cast acrylic panels for architectural features are increasingly popular. Their strength, light weight, and design flexibility make them ideal for:

As a professional OEM architectural acrylic panels manufacturer, OLEG’s capacity allows for large-format, custom-colored, and textured sheets that meet the scale and vision of modern architectural projects.

For impactful visual communication, cast acrylic is the preferred material for signage. Its machinability allows for crisp, routed edges and detailed engraving. Key uses include:

The material's consistency ensures that every letter and graphic element in a sign appears flawless, a critical factor for brand image.

Beyond aesthetics, cast acrylic serves critical functional roles. Thick cast acrylic sheet for industrial applications leverages its impact resistance and structural integrity. Examples include:

The non-porous, easy-to-clean surface of acrylic is ideal for hygiene-centric settings. Acrylic sheet for sanitary ware is used in:

A major strength of cast acrylic is its fabricability. How to cut and polish cast acrylic sheet is a common query, and the process is straightforward with the right tools:

This ease of fabrication, combined with the ability to order custom cast acrylic displays and panels directly from a manufacturer like OLEG, empowers designers and makers to realize highly specific project requirements.

The core difference lies in the manufacturing process. Cast acrylic is made by polymerizing liquid monomer in a mold, resulting in higher molecular weight, better chemical resistance, and superior thermoforming qualities. Extruded acrylic is made by heating and forcing acrylic through a die, which is faster but produces a material with slightly lower performance in these areas.

Yes, in terms of impact resistance. Cast acrylic is approximately 10-15 times more impact-resistant than standard glass of the same thickness. While it can be scratched more easily than glass, scratches can often be polished out, which is not possible with glass.

Absolutely. High-quality cast acrylic like that produced by OLEG contains UV stabilizers that protect it from yellowing and becoming brittle due to sun exposure. It is an excellent material for outdoor signage, architectural features, and protective barriers, often outperforming other plastics in long-term weatherability tests [2].

Cast acrylic is available in a very wide range of thicknesses, typically from as thin as 0.06 inches (1.5mm) up to 4 inches (100mm) or more for special orders. This makes it suitable for everything from delicate display items to heavy-duty industrial machine guards and aquarium windows.

Use a soft, lint-free cloth or sponge with a mild soap (like dish soap) and lukewarm water. Always rinse thoroughly and dry with a soft cloth to prevent water spots. Avoid abrasive cleaners, paper towels, or solvents like acetone or window cleaners containing ammonia, as they can damage the surface.

Cast acrylic sheet is a material defined by its quality-oriented manufacturing process, resulting in unmatched optical clarity, formability, and durability. From cast acrylic panels for architectural features to thick cast acrylic sheet for industrial applications, its versatility is proven. For specifiers seeking reliable, high-volume supply of material that consistently meets premium standards, partnering with an established manufacturer with integrated control from raw material to finished sheet—such as OLEG with its significant production footprint in China—provides a critical advantage in project success and longevity.

[1] Plastics Design Library. (2017). *Handbook of UV Degradation and Stabilization*. Elsevier Science.

[2] Kutz, M. (Ed.). (2011). *Applied Plastics Engineering Handbook: Processing and Materials*. William Andrew.