Virgin Mitsubishi Materials

Light Transmittance

Thickness Tolerance

Over 10 Years for Outdoor

In the realm of modern interior design, architectural cladding, and artistic fabrication, materials ...

In the realm of contemporary construction and interior design, material innovation plays a pivotal r...

In the world of versatile and high-performance plastics, cast acrylic sheet stands as a premier mate...

In the world of high-performance polymers, UV resistant acrylic stands out as a critical material fo...

Understanding PMMA Sheets and Their Applications The selection of the appropriate thickness for PMMA...

In an era where sustainability and durability drive material innovation, the fusion of eco-friendly acrylic and thick acrylic sheets represents a pivotal advancement in industrial applications. This integration combines environmental responsibility with structural resilience, offering solutions tailored to diverse sectors. Hangzhou Oleg International Trade Co., Ltd., a veteran in acrylic manufacturing with a decade-long expertise in casting acrylic sheets, exemplifies how these materials can be harmonized to meet evolving market demands.

1. Eco-Friendly Acrylic: Pioneering Sustainability

Eco-friendly acrylic, also known as biodegradable or green acrylic, is engineered to minimize environmental impact without compromising performance. Key attributes include:

Low VOC Emissions: Unlike traditional acrylics, eco-friendly variants utilize water-based Eco-friendly Acrylics Unity (EAU) technology, eliminating toxic solvents and reducing volatile organic compound (VOC) emissions.

Recyclability: Derived from recycled content or bio-based feedstocks, these materials align with circular economy principles.

Energy Efficiency: Production processes consume less energy, lowering carbon footprints.

Applications:

Renewable Energy: Wind turbine blades and solar panel covers benefit from eco-friendly acrylic’s UV resistance and light transmission.

Construction: Green buildings incorporate these sheets for skylights, facades, and noise barriers, leveraging their durability and recyclability.

Consumer Goods: Eco-conscious brands use them for packaging, furniture, and displays, appealing to sustainability-driven markets.

2. Thick Acrylic Sheets: Engineering Durability

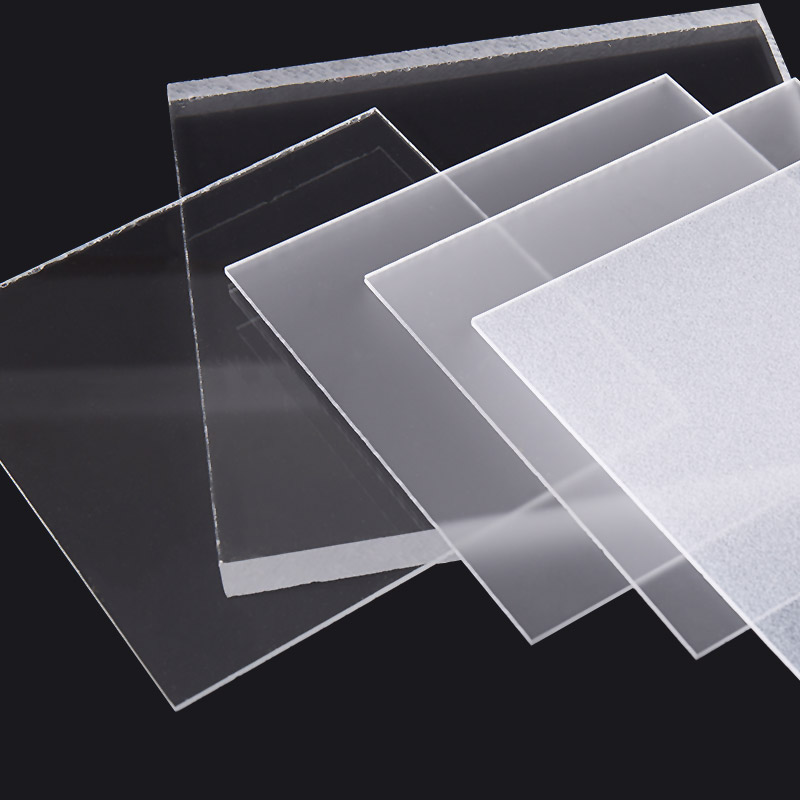

Thick acrylic sheets (typically exceeding 10mm in thickness) are renowned for their mechanical strength and optical clarity. Key features include:

Impact Resistance: Withstands pressures up to 200 times that of glass, making them ideal for safety glazing.

Optical Purity: Boasting 92% light transmittance, they rival glass in clarity while being half the weight.

Thermal Stability: Maintains integrity across temperatures from -40°C to 80°C, suitable for extreme environments.

Applications:

Aerospace: Aircraft windows and cockpit canopies rely on thick acrylic’s balance of strength and transparency.

Marine Industry: Aquariums and submarine viewing ports utilize its water resistance and pressure tolerance.

Retail & Exhibitions: Custom displays and signage leverage its machinability for intricate designs.

3. Synergy in Practice: Oleg’s Innovative Solutions

Hangzhou Oleg International Trade Co., Ltd. bridges these two domains by offering thick acrylic sheets manufactured via eco-friendly processes. For instance:

Sustainable Architecture: Oleg’s thick acrylic panels meet LEED certification standards, enabling zero-energy buildings to incorporate large-span, energy-efficient glazing.

Automotive Lightweighting: Their sheets reduce vehicle weight by 50% compared to glass, enhancing fuel efficiency while adhering to EU eco-design directives.

Art Installations: Custom-thickness, recycled acrylic sculptures showcase the material’s aesthetic versatility, from frosted finishes to vibrant, UV-stable hues.

4. Market Trends Driving Adoption

Regulatory Push: Global bans on single-use plastics and carbon tax regimes incentivize eco-friendly alternatives.

Consumer Demand: 68% of global consumers prefer brands with sustainable practices, per Nielsen’s 2024 survey.

Technological Advancements: Nano-coatings now extend thick acrylic’s lifespan to 30+ years in outdoor settings, reducing replacement cycles.

5. Challenges and Future Outlook

While eco-friendly acrylic addresses sustainability, scalability remains a hurdle. Oleg addresses this through: