Analysis of the manufacturing process of colored acrylic sheets: How to achieve high light transmittance and lasting color?

Color acrylic sheets are widely used in advertising signs, architectural decoration, home design, lighting art and other fields due to their rich color selection, excellent light transmittance and lasting weather resistance. However, different production processes directly affect the color stability, light transmittance and life of the sheets. As the leading manufacturer of cast acrylic sheets in East China, Hangzhou Oleg International Trade Co., Ltd., with 10 years of professional experience, will analyze the manufacturing process of high-quality colored acrylic sheets for you.

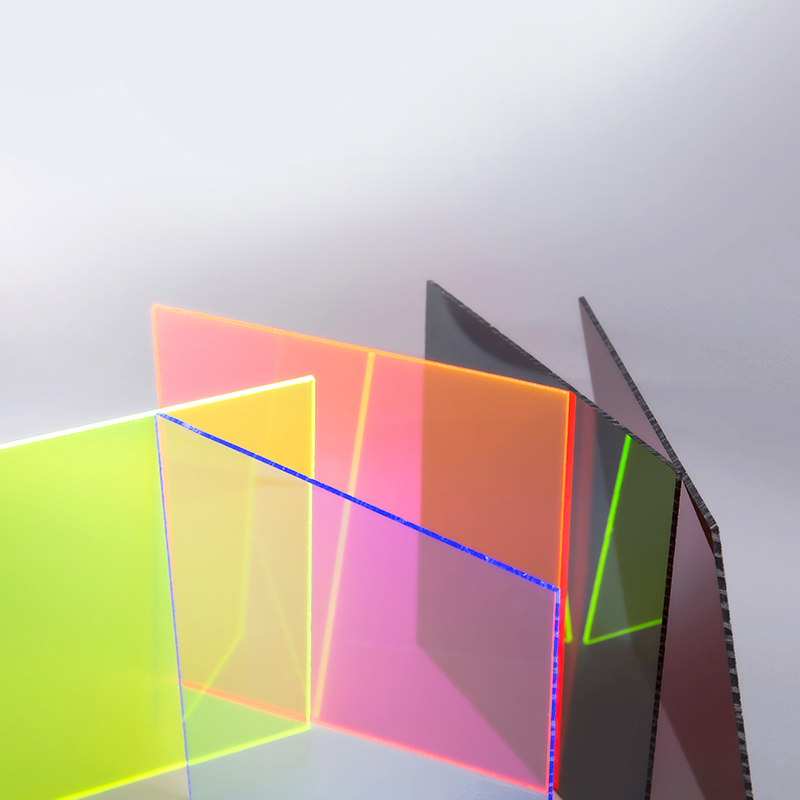

1. The key to high light transmittance: raw materials and casting process

Ordinary dyed acrylic sheets may have problems such as uneven light transmittance and excessive haze, while high-quality colored acrylic sheets must meet the following requirements:

High-purity MMA raw materials-ensure that the basic light transmittance of the sheet is ≥92% (close to optical grade).

Uniform dyeing technology-the color paste and liquid MMA are fully integrated to avoid color difference or precipitation.

Precision casting process - constant temperature polymerization system is used to make the molecular structure tighter, reduce internal scattering and improve light transmittance.

OLEG's solution:

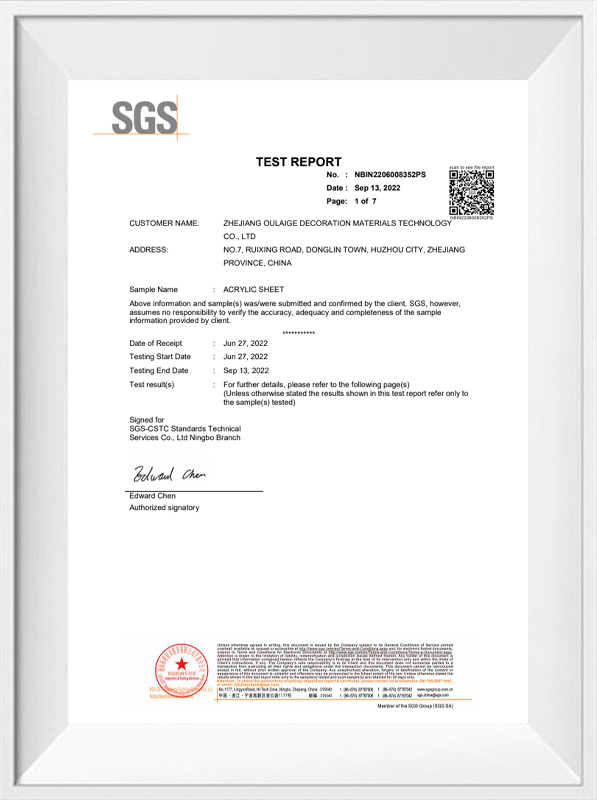

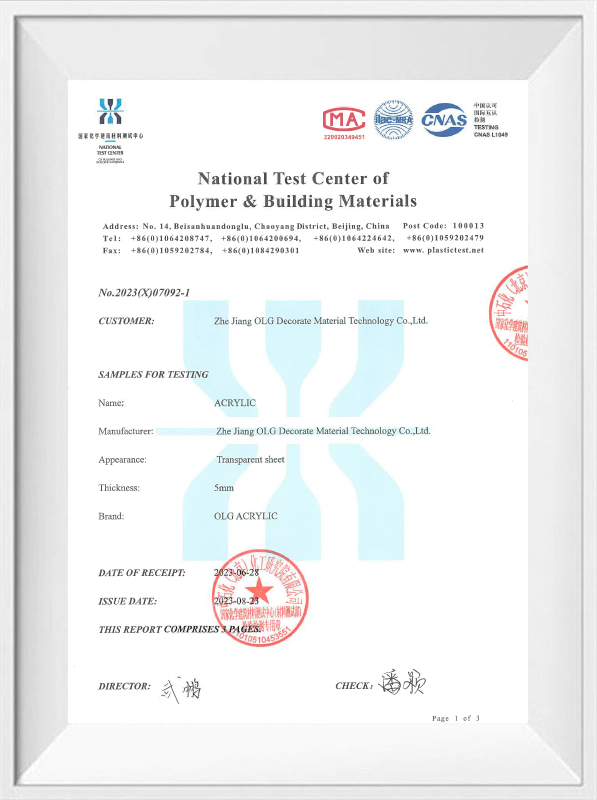

We use MMA monomer imported from Germany, combined with self-developed nano-scale color paste dispersion technology to ensure uniform color of each batch. During the production process, through fully automatic temperature control polymerization, the board is free of bubbles and impurities, and the light transmittance meets the GB/T7134-2008 quality product standard. The light transmittance of some products can reach more than 93%.

2. The core of lasting color: anti-UV and weathering treatment

Colored acrylic sheets used outdoors are easily affected by ultraviolet rays, temperature differences, and humidity, causing fading or yellowing. Lasting color requires:

Anti-UV additives - absorb or reflect ultraviolet rays to delay color decay.

High temperature/low temperature resistant formula - adapt to -40℃~80℃ environment, no cracking or deformation.

Surface hardening treatment - optional hard coating to reduce the impact of scratches on color.

OLEG's technical guarantee:

Our colored acrylic sheets are polymerized with UV stabilizers (not surface coatings) to ensure UV resistance throughout the entire sheet, and the outdoor service life can reach more than 10 years. At the same time, we provide a variety of surface treatment options such as frosted, mirrored, and textured to meet the aesthetic and functional needs of different scenes.

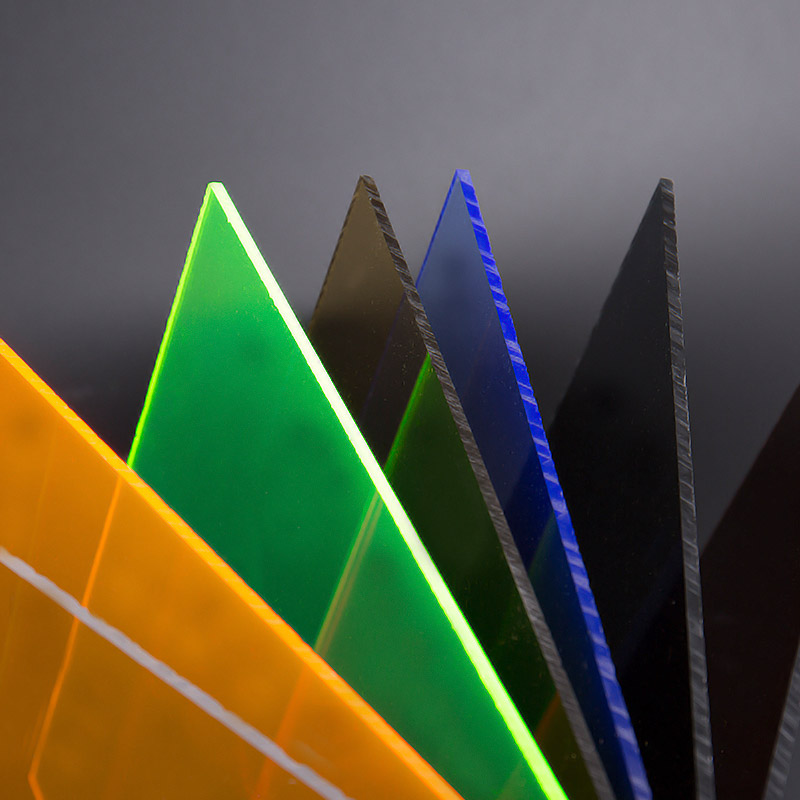

3. Special color effects: realization of metallic, fluorescent, and gradient colors

In addition to standard color systems, high-end applications (such as luxury goods displays and art installations) often require special effects:

Metallic texture - add pearlescent powder or metal particles to achieve a shiny effect.

Fluorescent/luminous color - use rare earth fluorescent materials, suitable for dark environment signs.

Gradient color process - achieve natural transition through multi-layer casting or special dyeing technology.

OLEG's customization capabilities:

Relying on Huzhou's 50,000㎡ production base and 6 fully automatic production lines, we can provide customers with customized services such as Pantone color card matching, gradient dyeing, and imitation marble, with an annual production capacity of 35,000 tons to ensure color consistency for large-volume orders.

4. Why choose OLEG colored acrylic sheet?

As the leading acrylic sheet manufacturer in East China, we provide:

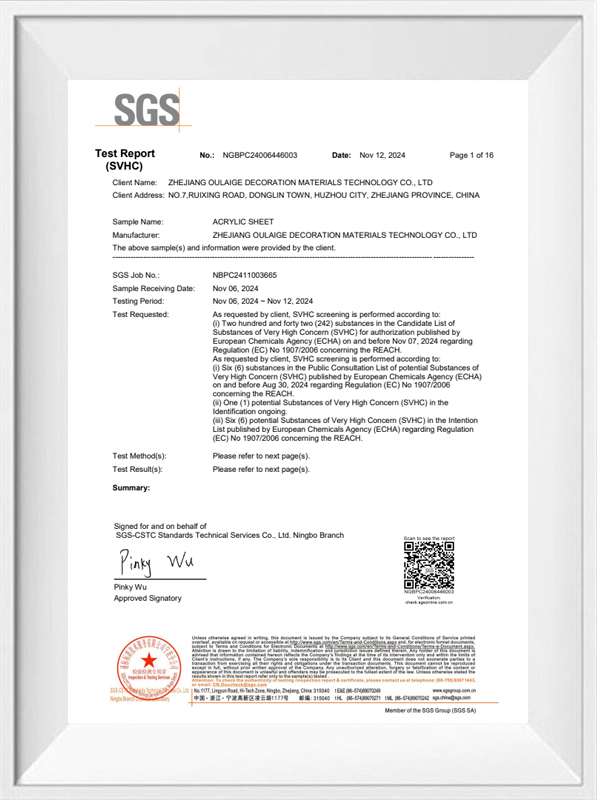

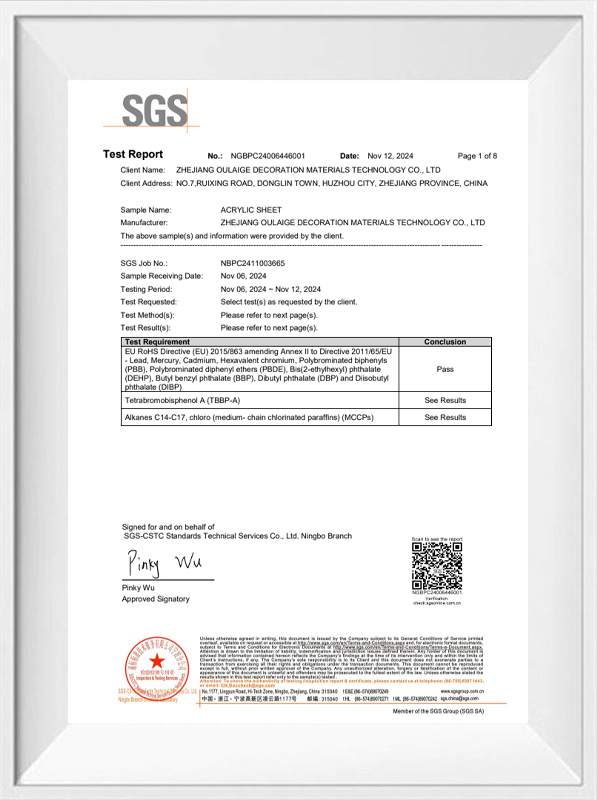

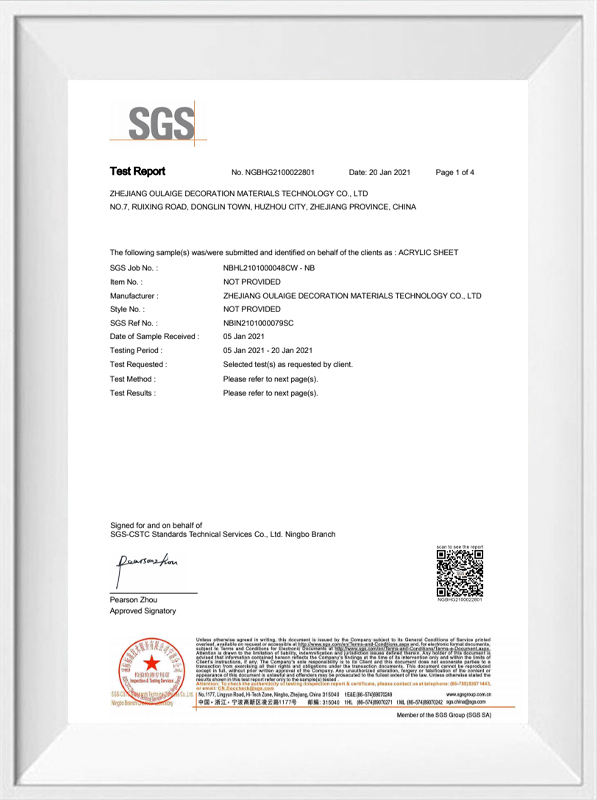

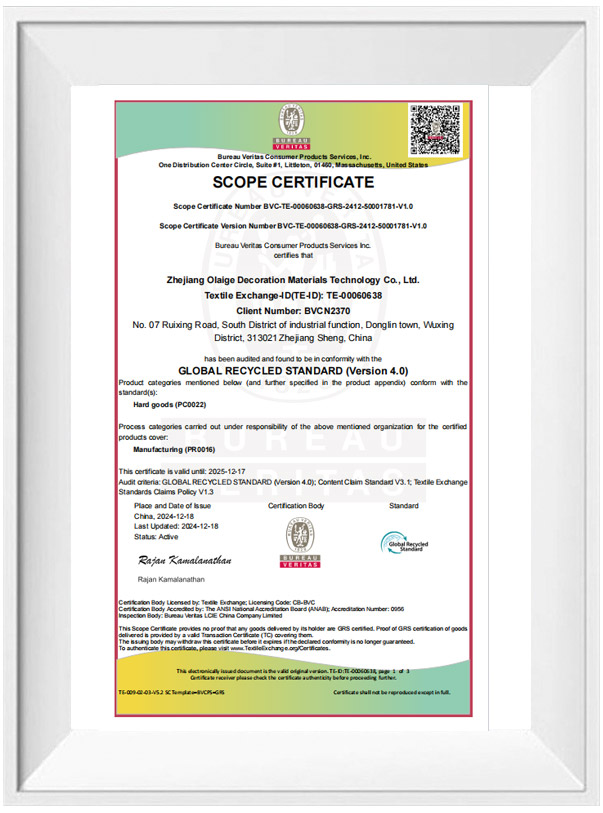

Full industry chain control - from raw material polymerization to finished product delivery, strictly follow the GB/T7134-2008 quality standard.

Color stability - using imported color paste + closed-loop temperature control system, color difference ΔE≤1.5 (industry leading).

One-stop service - supports full customization of thickness (1mm-100mm), size, and surface effect, suitable for building curtain walls, advertising light boxes, high-end exhibitions and other scenes.

Global supply experience - products are exported to Europe, America, the Middle East, and Southeast Asia, serving many Fortune 500 companies.