How to evenly distribute the glitter material in the patterned glitter acrylic sheet to achieve the ideal glitter effect? Is it added during the raw material mixing stage, or is it achieved through subsequent special processing?

Raw material mixing stage

Choose the appropriate glitter material: It is necessary to select the appropriate glitter material according to the desired glitter effect, such as gold and silver gold powder, silver powder, and colored sequins. The particle size, shape and material of these glitter materials will affect the final glitter effect and uniformity. Generally speaking, glitter materials with smaller and uniform particle sizes are easier to be evenly distributed in acrylic sheets. For example, gold powder, silver powder or sequins with an average particle size of about tens of microns can be better mixed with acrylic raw materials.

Precise measurement: Accurately weigh a certain amount of glitter material and determine the appropriate addition ratio according to the designed glitter effect and the specifications of the acrylic sheet. For example, if you want to make a patterned glitter acrylic sheet with medium glitter intensity, you may add 1-2 kg of glitter material to every 100 kg of acrylic raw materials. Accurate measurement is the basis for ensuring uniform and consistent glitter effects. Any slight deviation may lead to differences in the glitter effect of the final product.

Pre-dispersion treatment: Before adding the glitter material to the acrylic raw material, it is usually pre-dispersed. The glitter material can be mixed with a small amount of dispersant to make a pre-dispersion liquid. The dispersant can reduce the surface tension between the glitter material particles and prevent them from agglomerating during the mixing process. For example, a water-soluble dispersant such as polyvinyl alcohol is used to evenly disperse gold powder, silver powder or sequins in it to form a stable pre-dispersion liquid.

High-speed stirring and mixing: The pre-dispersed glitter material is added to the acrylic raw material and then stirred and mixed at high speed. High-speed stirring can quickly disperse the glitter material in the acrylic raw material and improve the uniformity of mixing. The stirring speed is usually controlled at about 1000-2000 revolutions per minute, and the stirring time depends on the amount of raw materials and the mixing effect, generally between 10-30 minutes. For example, for 500 kg of acrylic raw material and the corresponding proportion of glitter material, it may take about 20 minutes to stir to ensure that the glitter material is evenly distributed in the raw material.

Subsequent special treatment process

Vacuum degassing: The mixed raw materials may contain some air bubbles, which will affect the distribution of the flash material and the transparency of the acrylic sheet, and thus affect the flash effect. Therefore, vacuum degassing is required. Put the mixed raw materials into a vacuum tank, and gradually reduce the pressure in the tank to allow the air bubbles in the raw materials to escape. The vacuum degree is generally controlled between - 0.08 and - 0.1MPa, and the degassing time is 1-2 hours. Through vacuum degassing, the acrylic raw materials can be made denser, the distribution of the flash material in it can be more stable, and the flash unevenness caused by bubbles can be reduced.

Extrusion molding process control: During the extrusion molding process, parameters such as temperature, pressure and extrusion speed must be accurately controlled. The appropriate temperature can keep the acrylic raw materials in good fluidity, which is conducive to the uniform distribution of the flash material. Generally speaking, the extrusion temperature is between 180-220℃. At the same time, stable pressure and extrusion speed can ensure that the raw materials are evenly filled in the mold to avoid local accumulation or uneven distribution of flash materials. For example, the extrusion pressure is controlled between 5-10MPa, and the extrusion speed is adjusted according to the specifications and production efficiency of the acrylic sheet, usually around 1-5 meters per minute.

Cooling and shaping: The extruded acrylic sheet needs to be cooled and shaped to fix the distribution position of the flash material. The cooling speed also has a certain impact on the flash effect. If the cooling speed is too fast, it may cause stress inside the acrylic sheet and affect the uniformity of the flash material; if the cooling speed is too slow, it will affect the production efficiency. Generally, circulating water cooling is adopted to control the cooling water temperature at around 20-30℃, so that the acrylic sheet can be slowly and evenly cooled and shaped.

Quality inspection and adjustment: During the production process, the patterned flash acrylic sheet should be quality inspected, and the distribution of the flash material should be observed through optical inspection equipment. If the flash is uneven locally, it can be improved by adjusting the subsequent production parameters. For example, if it is found that there is less flash material in a certain area, the raw material flow rate in the extrusion process of the area can be appropriately increased, or the mixing process can be adjusted to make the flash material more evenly distributed.

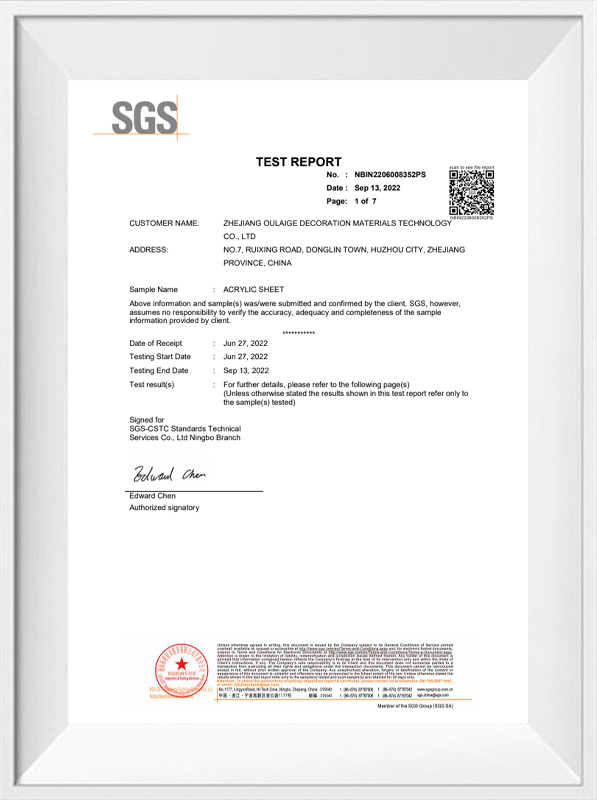

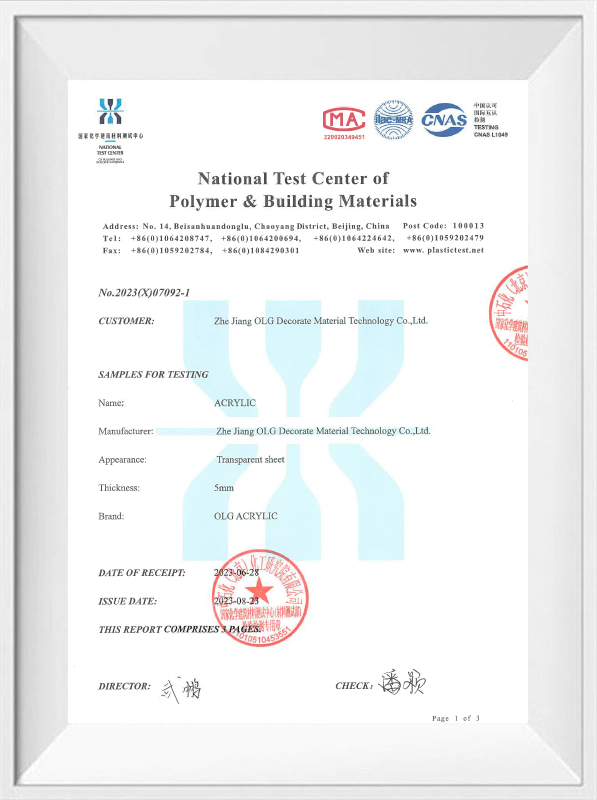

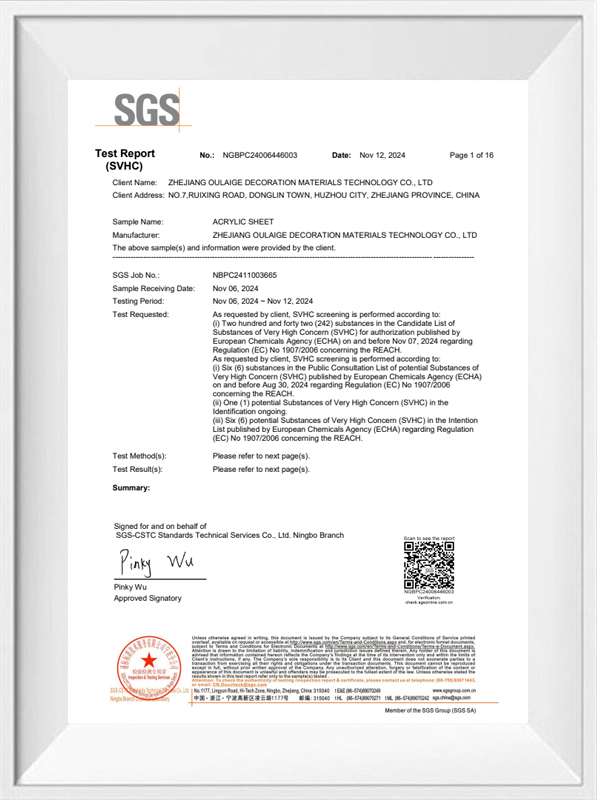

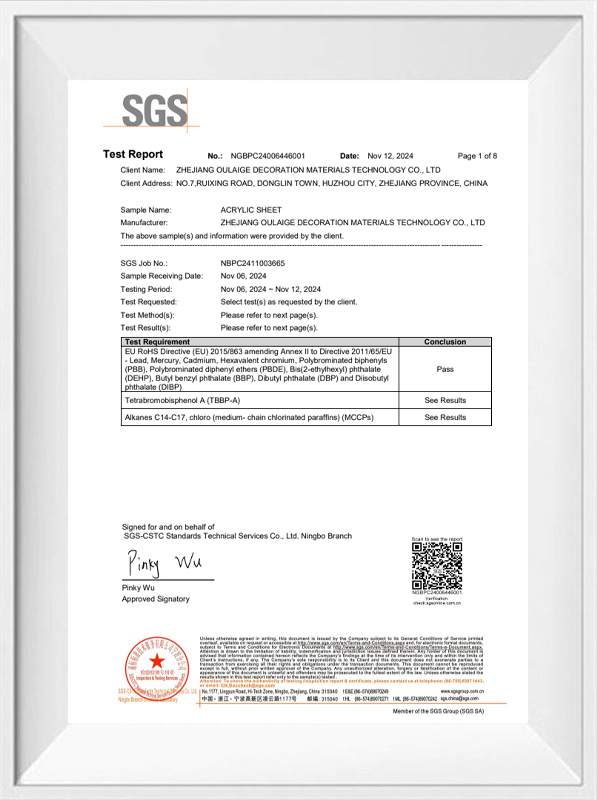

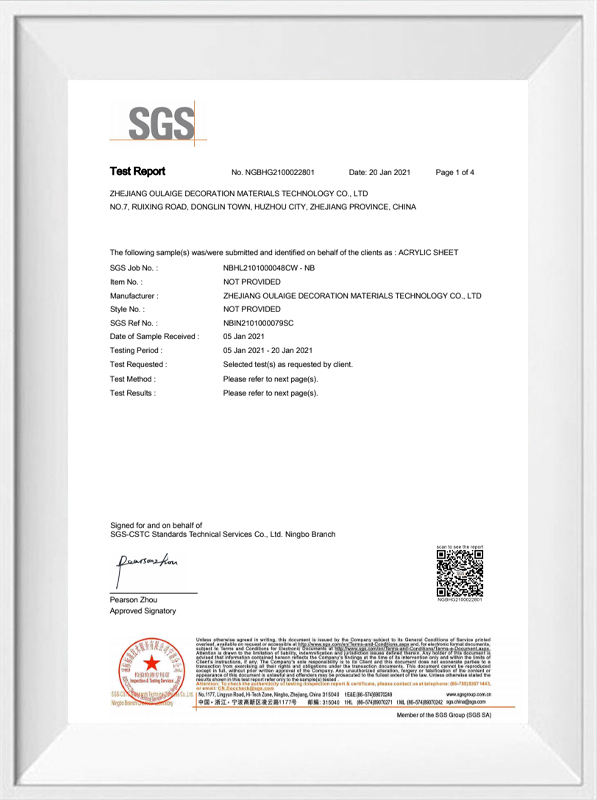

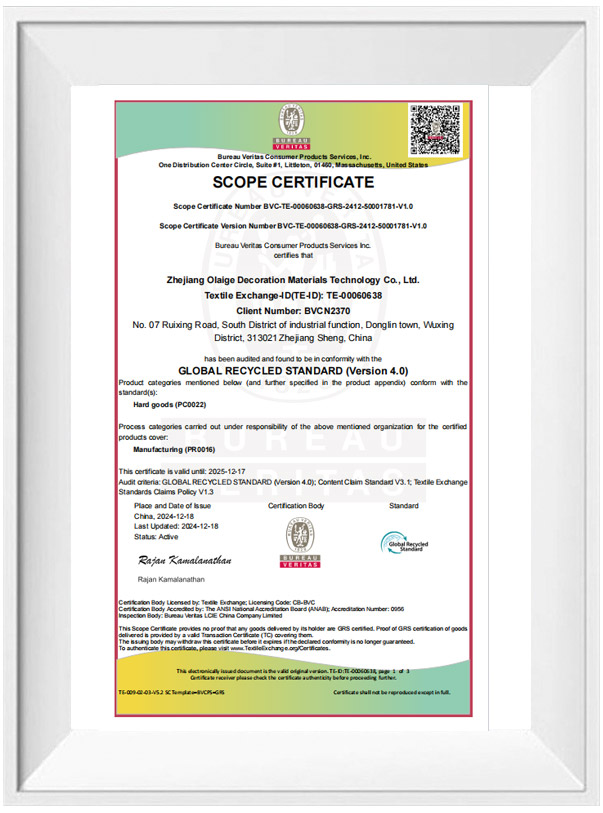

Hangzhou Oleg International Trade Co., Ltd. will certainly follow similar process when producing patterned glitter acrylic sheets to ensure that the products meet or even exceed the GB/T7134 - 2008 quality product standards. With ten years of experience in serving domestic and foreign customers, Hangzhou Oleg International Trade Co., Ltd. is able to continuously optimize production processes and provide professional solutions for the unique needs of volume buyers from all walks of life. Its products such as gold acrylic sheet gold powder, silver acrylic sheet silver powder and patterned glitter colored acrylic sheet sequins are carefully designed and strictly quality controlled to ensure quality, safety and reliability, bringing customers ideal glitter effects and visual experience. Through strict control in the raw material mixing stage and subsequent special treatment processes, it is able to produce patterned glitter acrylic sheets with uniform distribution of glitter materials and ideal glitter effects to meet the needs of different customers in the fields of high-end decoration, art production, DIY crafts, home decoration and commercial display.